· The machine is designed for versatility, accommodating a range of powder products from coffee to tea, and is adaptable to different packaging materials and box sizes.

· Capacity: 5-6 kg/batch (single unit), single extraction machine daily output 500L coffee concentrate, suitable for various classification products from coffee beans to coffee extract, covering a series of production processes from raw material processing to finished products.

·Our cold brew system can meet the needs of boutique cold brew coffee from small coffee studios to large roasting factories.

· Our cold brew system has the advantages of low single batch feed, high production efficiency, high extraction concentration, low energy consumption, and environmental protection. Therefore, this is a system developed for boutique cold brew coffee.

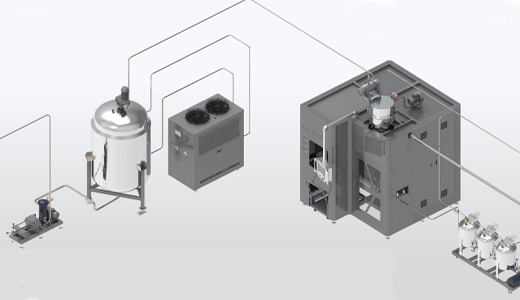

*Extraction system composition:

It consists of extractor/refrigeration unit/C.I.P cleaning tank 500L×3/filter/storage tank.

*Introduction to extraction assembly composition:

Configured with automatic weighing and feeding system;

The stroke of the brewing head is controlled by the electric cylinder, which is not easy to damage;

Automatic weighing and feeding while discharging slag, saving time;

Short extraction cycle. 10-15min.

Standard functions of espresso extractor

·The extraction tank adopts a flat structure to increase the contact area between coffee powder and water, reduce extraction time,

and improve extraction efficiency.

·The brewing head adopts a porous and evenly distributed structure with a pore size of 1.5mm. To ensure that the water output

can be evenly distributed on the surface of the coffee powder so that the coffee powder will not be penetrated during the soaking

process.

·One-click curve replication, stable production

10-inch industrial touch screen, full-chain automation system, inspection and monitoring of products in the production process to ensure

that the products meet quality standards.

And can save a variety of extraction curves, accurately retrieve, to ensure product consistency.

·Flexibly adjust the formula to meet personalized needs

You can make a variety of formulas by adjusting parameters such as pressure, time, and powder volume - from concentrated to American style,

to meet personalized production needs, with an average of 500L of stable production per day.

3.German craftsmanship and Italian classics

German-style Italian craftsmanship:

In-depth integration with coffee philosophy, minimalist industrial design carries the core of precision machinery, and modular structure

combines artistic texture and durability.

Traditional Italian espresso:

Replica of traditional Italian espresso, 9Bar;

Pressure/±0.5℃ temperature control system, achieving industrial quantitative gold cup.

Italian industrial extraction machine, combining German technology with Italian classics, opens a new era of industrial coffee extraction.

Benefits of Espresso Extractor

System Features and Benefits | |

Automatic powder feeding | Uses control to achieve automatic weighing and feeding. |

Automatic extraction | *Can set water inlet temperature, extraction pressure, and extraction time *Automatic powder feeding and automatic slag discharge. Continuous extraction is possible. *Use TDS to monitor the concentration of the extract, and remind the staff to adjust the extraction curve when it is lower than the set value. |

Secondary extraction | Using high pressure and low temperature water, you can get a better flavor extraction in the front section. The lower concentration of the extract in the back section is pumped into the circulation tank, and the next time the new coffee powder is extracted, the concentration is increased. |

Online grinding/extraction | Can be used with a grinder for real-time grinding, metering, transportation, and extraction; continuous operation to reduce coffee powder oxidation and aroma loss. |

High yield/high aroma | *Using high pressure and high temperature water, high yield extract is produced, with a yield of about 20% (the yield varies depending on the bean variety, extraction temperature, and extraction pressure). *The closed pipeline cools the extract in time to reduce aroma loss. |

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat