The following is a rotary two-column machine that can produce 50-60 capsules per minute. It is fully automatic and efficient, with a rotary design and a small footprint. It is very suitable for start-ups and is a very popular model. Next, I will introduce the functions of the machine step by step.

The coffee cup falls vertically into the stainless steel capsule storage tube,

The coffee cup falls vertically into the machine mold

The principle of the vertical cup drop method is that after the cups are stacked, there will be a gap between the two cups. Our special cup separation device separates the upper and lower layers of cups and uses a suction cup to absorb the bottom of the cup. This can achieve a 100% cup drop rate

The machine is suitable for different cup types, such as Nespresso cups, K-cup, Dolce Gusto cups, Lavazza Blue cups, Nespresso Vertuo cups, and can also be customized according to customer requirements. 50-70 cups can be dropped onto the disc per minute.

This machine is equipped with a cup detection system. If no cup is detected, the detector will send this information to the machine and sound an alarm, and the filling and sealing process will not be carried out at that position.

Servo motors control the coffee filling augers. Each augers is equipped with a motor. The parameters of each augers can be easily adjusted

A critical step to ensure the quality of the seal. Failure to clean up the powder residue will result in a poor seal, poor brewing results, and nitrogen loss, which will shorten the shelf life of the coffee.

Suitable for various sealing materials such as aluminum, plastic, paper, etc. Suitable for films with or without printing.

The intelligent sensing system helps you better control the production line. When the capsule is used up, the machine will stop filling and sealing. When there is no cap, the machine will stop sealing and stop working. If there is a continuous lack of cups in the mold, the machine will stop and sound an alarm.

The heat-sealing coating at the front end of the diaphragm melts and sticks to the cup mouth to complete the sealing.

The entire device is driven up and down by the main motor. It effectively ensures the safety of the chain, template and sealing device.

Rapid sealing technology effectively protects the capsule and sealing material. The sealing temperature can be adjusted within the range of 0-400 degrees Celsius.The function of heat sealing is to make the membrane fit tightly to the mouth of the cup to prevent air leakage.

After the finished coffee capsules are completed, the cup will fall into the finished product frame, and it can be shipped after packaging.

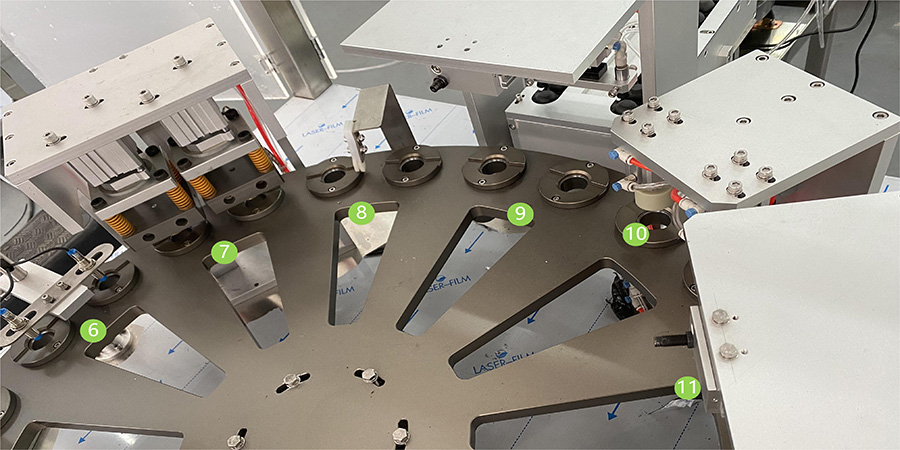

Step⑧⑨⑩ is the option function for freeze-dried coffee.

①Vertical Cup Dropping

②Cup-absence detection

③Servo filling system

④Cleaning cup rim dust

⑤picking up the film

⑥no film no filling

⑦heat sealing

⑧ear folding

⑨lid bucking

⑩lid detection

⑪finished product output

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat