*This rotary type Nespresso capsule filling machine is full automated, high efficient, which can produce 2400 Nespresso capsules per hour. With an intelligent PLC control system for ease of operation, minimizing labor and costs.

*This rotary type is one of the most popular Nespresso capsule filling machine,not only can helped small and medium-sized customers get started, as well as helped large enterprises to expand their production.It offers an ideal solution for businesses looking to meet both daily production demands and maintain high-quality standards.

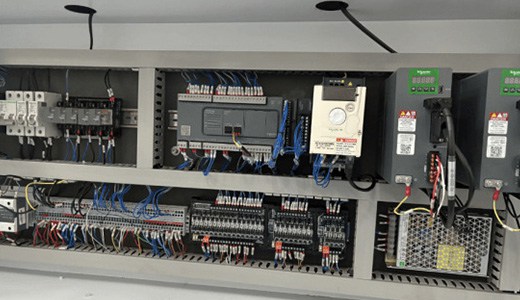

*Omron control system will ensure reliable power to drive the whole line. Also can use other brands like Allen Bradley, Schneider, Mitsubishi as per your requirement.

1. The RN1S nespresso capsule filling sealing machine is widely used for coffee powder, tea powder/granules, cocoa powder, milk powder, instant powder,

and other fine powders and small, flowable granules.

2. This machine can customized to produce liquid, paste, and other products, such as packaging of cosmetics, liquid health products.

3.This machine can easily replace different mold plates to produce different types of coffee capsules,such as K up Dolce Gusto, lavazza capsules and K cups, etc.

Model | HP-R1 |

Suitable for | plastic/aluminum/bio Nespresso capsules, Dolce Gusto capsules, K cups, Lavazza capsules, etc Pre-cut aluminum foil or Rolled film can be chosen by your side. |

Capacity | 30-40cups/min (adjustable) |

Filling type | The Servo motor is a driven auger filler |

Filling accuracy | ±0.1g-0.15g |

Sealing type | Pneumatically driven heat and seal, Omron precise temperature controller to adjust |

Voltage | 220v 50/60hz—1PHASE (by customer) |

Dimension | 1200(L)*1000(W)*2150(H)mm |

Weight | 1000kg |

Compressed air consumption | 0.2-0.3 m3 per minute @ ≥ 0.6Mpa |

*Compact design,Small footprint, suitable for perfect for space limited production area.

*Servo Motor controlled filler, filling accuracy is stable and high in 0.2 grams error.

*Constructed with stainless steel 304, this machine ensures long-lasting performance and adherence to food safety standards.

*Most of our machine accessories are Omron, Schneider and other famous brands, the machine is more durable and stable.

*Open design: The machine has an open design that makes it easy to clean and maintain.

*Nitrogen system: the machine can be directly connected to the nitrogen generator.

Empty capsules are made of plastic materials, which are hard, not easily deformed, and can be using a specialized

separator to create a gap between stacked cups. A suction cup then lifts the bottom cup, ensuring 100% successful separation.

High filling structure, fast speed, high precision, no dusting.

Vertical Augers: Ensure even and fast coffee distribution.

Leak-proof Nozzle: Covers capsule edges fully to prevent spills.

This step is essential for maintaining seal quality. If powder residue is not removed, it can result in weak sealing,

reduced brewing efficiency, and nitrogen leakage, ultimately shortening the coffee's shelf life.

High vacuum pressure ensures complete removal of coffee residue from the capsule edges.

The coffee is compacted to create a firmer texture, enhancing the brewing process.

Advanced sealing technology safeguards the capsules and sealing materials.

The sealing temperature is adjustable, ranging from 0 to 400 degrees Celsius.

High-quality Japanese heat insulation materials are used to protect the cylinder and heater-related components from high-temperature damage.

Heaters and thermocouples are designed for easy replacement.

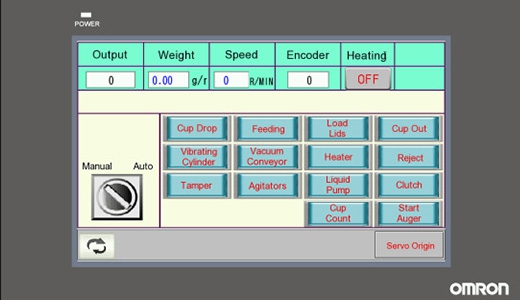

Easy to operate. English can be set as the operation language.

Operation State is clear at a glance.

Counting function counts the amount of cups produced.

It can work for 24 hours working without stop.

Fault display will help indicate issue.

All the electrical parts are mainly from Schneider and Omron to ensure working accuracy of all functions.

All the parts are standard that it is easy for you to find the replacing ones.

Spare output port can help realize multi-unit chain control and remote diagnosis control.

This nespresso filling packaging machine is very popular with small and medium-sized customers, customer either use self-designed

capsules or package standard nespresso capsules, and this machine is very easy to use and maintain, also can expand their production.

1.2 years warranty

2.Customize service available:we can provide you with different packing solutions for different customers.

3.In-person and Online Training

4.Videos/books manual

5.Also purchase empty Kcup and film for our customers, providing them with a one-stop service.

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat