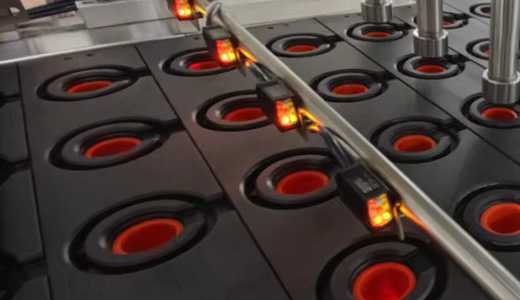

• This is a liner type k cup filling machine with 4 working lanes,which can produce 120-160 k cups per minutes. The cup model can be customized and can fill various materials such as coffee powder, milk powder, tea, etc.

• The machine frame is made of 304 stainless steel, equipment parts are processed by high-precision processing equipment,offers long-lasting performance with minimal maintenance requirements, ensuring reliable operation over time.

• The machine is suitable for filling and sealing Nespresso, K-Cup, dolce gusto, and Lavazza coffee pods, can meet various customized needs of production lines.

The main engine and parts are made of 304 stainless steel and aluminum, the pneumatic components use Yadker, SMC, Festo and other brands,and Electrical components adopt Siemens, Omron, Schneider and other brands.

Model | HP-L3 |

Work Lanes | 3 |

Capacity | 120-160 Kcups/min (adjustable) |

Filling type | The Servo motor is a driven auger filler |

Filling accuracy | ±0.1g-0.15g |

Sealing type | Pneumatically driven heat and seal, Omron precise temperature controller to adjust |

Voltage | 3 phase 220V @ 50/60hz - 3kw(by customer) |

Dimension | 4600mm*2400mm*2800mm |

Weight | 1500kg |

Compressed air consumption | ≥0.6Mpa/300L per minute |

The manipulator automatically grabs and puts the cup;

Self-made linkage mechanical transmission device, stable operation and stable grasp cup. When entering the template, the bottom has the suction cup under the pull, so that the cup is 100% stable entry.

Cup detection

Omron induction photoelectric, to detect the absence of a cup body.

Servo screw feeding

The Siemens servo motor drives the precision screw feeding to ensure the filling accuracy.

Film absorption, film release

The aluminum foil film on the membrane frame is absorbed by the vacuum, and the film is put into the mold positioning hole by the independently designed flipped 180° device. There is a guide groove in the mold hole.

.

.

The finished product enters the conveyor belt, and the waste product is removed to the waste bucket

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat