• The Drip Coffee Packaging Machine is an automated precision packaging system for coffee/tea, utilizing ultrasonic sealing and sliding discharge mechanisms to preserve product integrity.

• It integrates Mitsubishi PLC controls,Panasonic servos, a 10-inch HMI, and intelligent alarms for operational stability.

• Hygienic SUS304 stainless steel construction combines with PID temperature regulation and servo-driven film control to ensure sanitary conditions and premium packaging quality.

The drip coffee packing machine serves as a versatile automated solution for precision unit-dose packaging of

small-particle products in both inner and outer pouch configurations, including popular formats like drip coffee

sachets (also known as ear-hook coffee, pour-over coffee, filter coffee, or single-serve brew bags), tea sachets,

and pre-portioned coffee pouches. This system efficiently handles the hygienic encapsulation of loose ingredients

while maintaining freshness, catering specifically to the growing market of instant-brew beverage formats

that combine convenience with artisanal preparation experiences.

Specifications of Drip coffee packing machine | |

Bag type | 3 sides sealing |

Packing speed | 1200-1800 bags/hour |

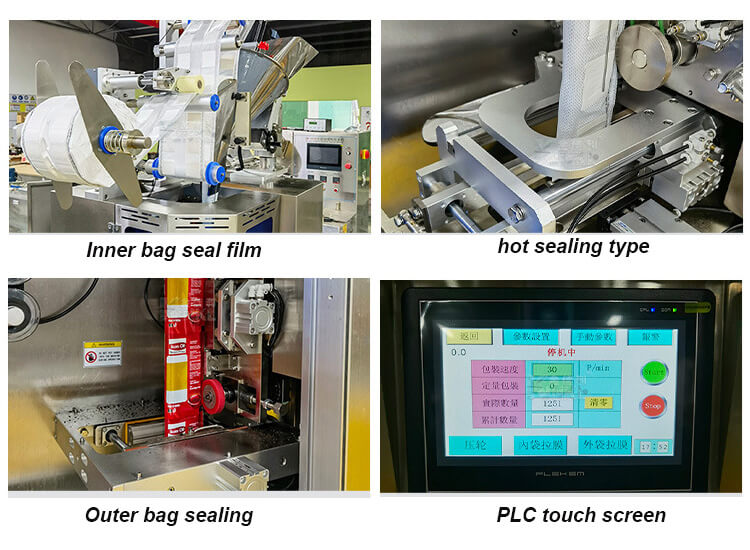

Sealing type | inner bag sealed with high temperature Outer bag sealed with hot sealing type |

Inner filter bag size | L(50mm-70mm)*W(45mm-80mm) |

Outer bag size | L120mm*W100mm |

Filling range | 1-20 g |

Packing machine Dimension | L 1650×W 860×H 2350mm |

Weight | 660kg |

Voltage supply | 220v 50HZ 3.5kw |

Applicable Scope:This machine is designed for single-dose inner/outer bag packaging of small-particle materials such as tea leaves,

herbal teas, health supplement granules, and similar products.

Packaging Control:Stepper motor-driven film feeding ensures stable bag length and precise positioning for both inner and outer pouches.

Temperature Control:Equipped with a PID temperature controller to enhance sealing accuracy and adaptability across diverse materials.

Human-Machine Interface:PLC-controlled operations with an intuitive HMI display guarantee hygiene reliability and user-friendly production monitoring.

Packaging Materials:Compatible with tea filter paper, cotton thread, composite films (e.g., PET/AL/PE), and custom-printed labels.

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat