BALLE COFFEE planned to launch a new product line of small-cup ready-to-drink coffee with 20ml per cup.

To meet rapidly growing market demands, the client needed an efficient and stable automated filling production line

to improve productivity and ensure product quality.

• Traditional manual filling methods were inefficient for mass production

• Manual operation led to unstable filling volume affecting product quality

• High labor costs and difficult hygiene control in production processes

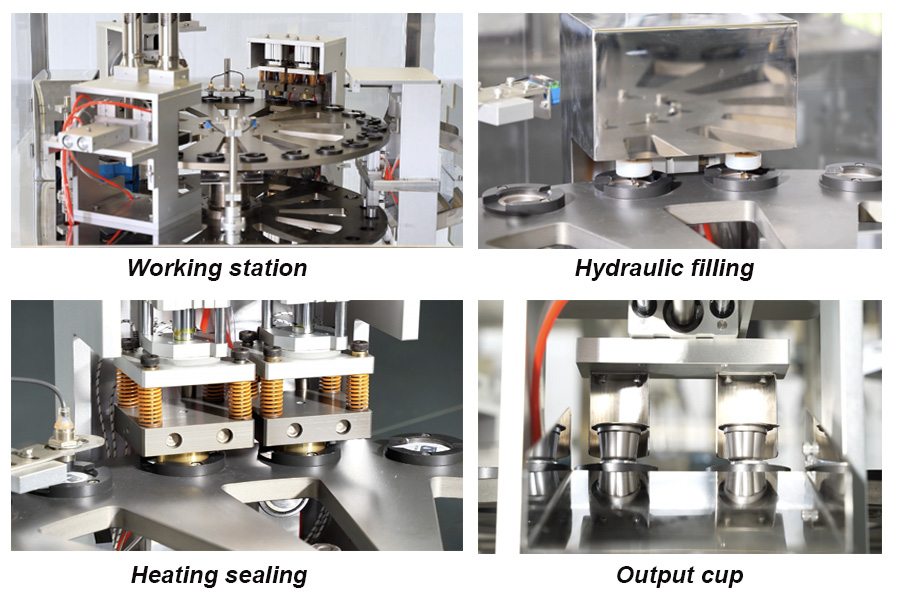

We provided the R2 Automatic Rotary Filling and Sealing Machine for cup coffee liquid:

• Automatic cup loading system

• High Precise filling system

• Efficient heat sealing device

• Intelligent control system

• Automatic date coding function

• Production Speed: 80 cups/minute

• Filling Accuracy: ±0.2

• Applicable Cup Size: 10-20ml

• Equipment Power: 3.5kw

• Air Pressure Required: 0.6-0.8MPa

• Fully automatic operation with simple control

• Precise filling with excellent product consistency

• Low failure rate and easy maintenance

• Quick changeover for different product specifications

• Compliant with food-grade hygiene standards

After implementing the equipment, the client achieved significant benefits:

• 100% increase in production efficiency, reaching 50000 cups daily

• 60% reduction in labor costs, from 8 workers to 2

• Significantly improved filling accuracy, defect rate below 0.1%

• Fully automated operation ensuring product hygiene standards

Through this automatic coffee packaging solution, we not only helped our client improve production efficiency

and reduce production costs but also provided reliable quality assurance for their coffee liquid products, won a good reputation.

Contact: Ada Xing

Phone: +86-17749792298

E-mail: adaxing@hepacking.com

Whatsapp: 8617749792298

Add:

We chat